Product

S-Series Mini Rack Oven

- Strong insulation.

Ensures that the heat stays in the oven chamber. - Stainless steel inside and out.

Maintains low temperature and is easy to keep clean. - Large front window with heat-reflecting double glass and good lighting.

Gives a good overview of the baking process. - Built-in, high-capacity steam system.

Fast function and energy-saving. - Right hand hinged door with double glazed window.

Easy to open and overview. - Canopy as standard

- Aluminum legs and castors as standard

- Max baking temperature 300 degree C.

- Gas model SR242 SRP242 now available (with single stage burner)

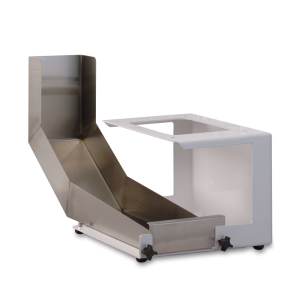

C-Series Rack Oven (pictured with optional ramp)

The C-series is the Sveba-Dahlen range of compact rack ovens, designed for installation in restricted spaces. A small footprint, highly effective, simple and flexible, are key characteristics of the rack ovens of the C-series.

- Can be run on electricity, oil or gas.

- Strong insulation.

Ensures that the heat stays in the oven chamber. - Stainless steel inside and out.

Maintains low temperature and is easy to keep clean. - Large front window with heat-reflecting glass and good lighting.

Gives a good overview of the baking process. - Large, efficient heating package.

Fast heating and energy-saving. - Right hand hinged door.

Easy to open and overview. - Max baking temperature 330°C.

- Including suspension hook.

V-series Rack Ovens

- Robust oven designed for industrial use!

- Energy efficiency thanks to the intelligent energy-savings functions and well-insulated oven space.

- Highly effective long life stainless steel heat exchanger gives great total economy.

- User friendly, smart control panel that gives the user complete control of the entire baking process.

- Powerful, quick and extra clean steam system – a uniquely developed, stainless steel system with both even and efficient capacity as well as rapid recovery.

- A horizontal airflow developed to give a very even baking result across the rack (even for sensitive bakes with short baking times).

- Slow start/stop functionality for the gentle handling of sensitive products such as meriques and macaroons.

- Rotating rack with optimized rotation speed and automatic change of rotation direction using the rack, given an even bake with better results.

- the oven also has a quick cool down functionality (forced fan) which makes the temperature setting down to a lower temperature, to the next bake, really fast.

- Can be run on electricity, oil or gas.

I Series Rack Oven

- Highly efficient long life stainless steel heat exchanger giving you great total economy.

- A horizontal airflow gives a very even baking result across the rack, even for sensitive bakes with short bake times.

- A uniquely developed steam system with both even and efficient capacity as well as rapid recovery, resulting in a greater production capacity.

- low noise level.

- Energy efficient thanks to the intelligent energy-savings functions and well insulated oven space.

- Rotating rack with optimized rotation speed and automatic change of rotation direction using the rack, gives an even bake with better results. Our patented IBS (Increased Baking surface) for alternating rotation of the racks.

- User-friendly control panel that gives the user complete control of the entire bake process.

D- Series Classic Deck Oven

- Available in five standard widths and up to five sections in height, standard crown height 160 mm, optional height 220 mm available. Suited for most tray and bread sizes.

- Designed in a flexible module system with many options. Gives each bakery the ability to create the oven that suits their needs best.

- Each oven section can be individually controlled with separate settings of the top, bottom and front heat. Full control in the baking process.

- Well insulated oven chamber. Keeps the heat inside the oven.

- Stainless steel front. Maintains low temperature and is easy to keep clean.

- A range of accessories such as steam generator, stone hearth makes the Classic adaptable to all the customers’ needs.

- Including aluminum legs with adjustable feet.

- Choice of control panels.

Classic Pizza Oven

- Available in four standard widths and up to three sections in height, standard crown height 160 mm.

Suited for most pizza sizes. - Designed in a flexible module system.

Gives each pizzeria the ability to create the oven that suits its needs best. - The well insulated oven chamber keeps the heat inside the oven.

- Stainless steel front is easy to keep clean.

- Stone soles – Classic pizza baking requires solid stone soles.

- Halogen lights provide whiter and more intensive working light than standard bulbs.

- Oven control – Each oven section can be individually and stepless controlled with separate settings of the top, bottom and front heat. Full control in the baking process. Easy to handle, understand and program.

- Unloading shelf and castors.

Convenient details that makes handling and baking easier.

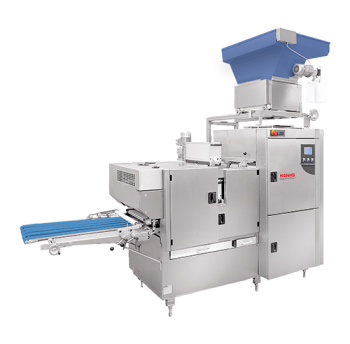

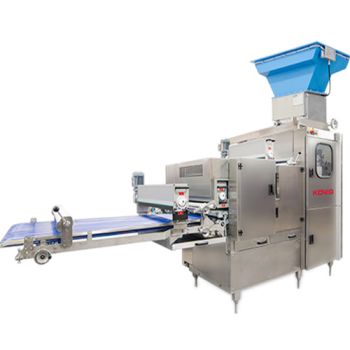

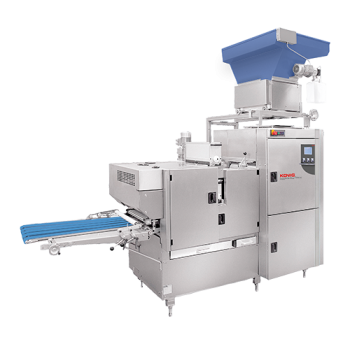

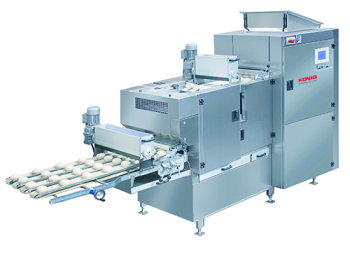

KOENIG Artisan SFC

- wide feeding belt for convenient dough feeding

- dough belt duster with large storage container and controllable drive for even dusting of the dough belt

- touch panel with pictograms for language-independent operation

- quick and easy adjustment of the machine by means of pre-installed standard programs

- max. 50 programs can be stored

- guillotine and stamping station for a maximum product variety

- dough sheet calibration system by means of innovative calibration ledges

- optionally available with dampening and seeding unit

OLIVER Mini-Vert Air Bread Bagger 1170

1170

- mounts directly to your slicer or bench

- Complements Oliver 797 Chute-fed bread slicers

- up to 1,200 packages/hour

- product capacity: 5″ wide

- bag specifications: 9″wide minimum 32″ long maximum

- Inflates bread bag so that sliced bread can be quickly bagged

OLIVER 797 Gravity Feed Bread Slicer

797N

- Batch slicing for higher volume retail and in-store bakeries

- 32″ infeed chute with Proguard and single loaf pusher

- Proguard feature supports industry safety guidelines

- single loaf pusher gently and safely guides loaf into blades

- heavy duty castors

- Blade advantages:

- Uses the lowest cost replacement blades in the industry, contributing to low cost of ownership

- Easily replaceable, independently mounted, rust-resistant blades

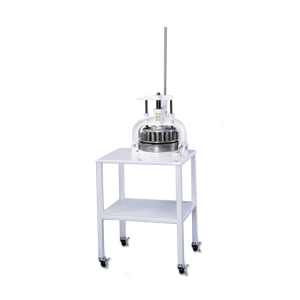

GLIMEK SD-180 Suction Dough Divider

SD-180

- Weight range, 3 versions, 35 up to 2300 grams

- Variable speed with frequency converter

- Capacity 750 up to 1800 pieces per hour as standard

- Stainless steel dough knife

- Unique emptying function (hopper reaches all the way down to the knife)

- Gentle dough handling

- Easy handling and cleaning – all covers are in stainless steel and are removable

- 100 liter stainless steel hopper as standard

- 225 liter stainless steel hopper (optional)

- Non stick coated hopper (optional)

- 17 liter oil reservoir, easy to fill

- Extremely silent 72 dB(A)

OLIVER 723 Bagel & Bun Classic Slicer

723

- cleanly slices everything from sub buns to bagels with ease

- adjustable slice height setting

- separate on/off buttons

- exclusive “gentle-touch” door slows the exit of the bun to help prevent damage

- optional return chute available

OLIVER ProGuard for Gravity Feed Slicer

797

- Required by Ministry of Labor for all gravity feed bread slicers

- ProGuard helps prevent employee hands or fingers from coming into contact with the blades from loading end

- Machine can be loaded with power off and guard open

- Additional loaves must be loaded from end of guard while machine is in operation

- Auto shut-off feature when guard cage is opened

- Additional out-feed guard secures out-feed table from opening while machine is in operation

- ProGuard retrofit kit must be installed by trained and authorized service dealers

- ProGuard retrofit kit for use on machines manufactured after 1979

- ProGuard comes standard on all new 797 Gravity Feed Slicers sold into Ontario Canada

GLIMEK CR400 CONICAL DOUGH ROUNDER

CR400

- Centrally adjustable rounding tracks

- Capacity up to 4000 pieces per hour, this is subject to dough weight and dough characteristics

- Weight range from 30 up to 1800 grams, this is subject to dough characteristics and capacity

- Non-stick coated cone and tracks for better rounding

- Rounding length up to 4 meters

- Operation panel easy accessible from both sides

- Easy to clean

GLIMEK IPP Intermediate Pocket Prover

IPP

- Three different infeed systems

Adapted to customer needs - Dual infeed

For capacity up to 3000 pcs/h - Electrical cabinet

The dough divider, conical rounder and moulder is connected to the IPP - IPP pocket prover

The IPP is a modular pocket prover that is adapted to the customers needs when it comes to capacity per hour and resting time.

The standard execution consists of 6, 8 or 10 cups per swing, A robust construction, swings and cover plates and manufactured in stainless steel

OLIVER 777 Variety Slicer

777

- Slices virtually all varieties of bread cleanly and quickly

- Compact, sturdy design is easy to use

- Automatically holds bread in place during slicing

- recommended for slicing up to 150 loaves per day

GLIMEK MO300 Dough Moulder

MO300

The MO300 is available with a wide variety of options to suit the customers needs.

- Centrally adjustable infeed

Enables a correct positioning of the dough piece - Two pair of 400mm wide adjustable pressure rollers

With spring loaded scrapers for easy cleaning - Collection tray with two positions

Enables straight line outfeed - Capacity range up to 3000 dough pieces per hour

- Weight range from 30 up to 1800 grams

- Working width up to 650 mm

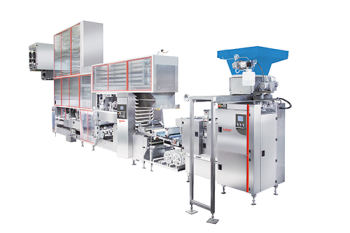

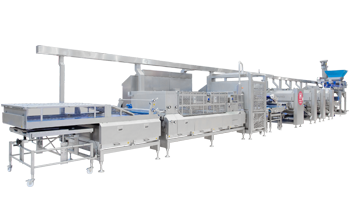

GLIMEK Flexible Bread Line – Bread Line 180

180

The Flexible bread line is very user friendly and flexible with a high capacity and efficiency.

It handles a wide variety of dough types and sizes which makes the bread line very flexible and efficient. The Flexible bread line consists of the following freestanding machines:

- SD-180 Dough Divider

Weight range from 120 to 1600 g, variable speed with frequency converter for 750 up to 1800 pcs/h, 100 liter stainless steel hopper with non stick coating. The SD-180 in the picture is equipped with a flour duster. - CR-400 Conical Rounder

The CR-400 has centrally adjustable non-stick coated tracks, infeed at 6h, outfeed at 12 h and outfeed chute and mechanical flour duster. - IPP 6/22 Intermediate Pocket Prover

Intermediate pocket prover with 132 effective pockets, single infeed V-belt conveyor. Its equipped with photocell controlled non-stick coated infeed conveyor with continuous pocket prover drive. The prover has variable speed and the electric control panel is situated under the projecting overhang for easy control. The IPP has power supply for the divider, conical rounder and the moulder. Max proving time is 4,3 minutes at 1800 pcs/h. - MO-300 Moulder

The moulder has centrally adjustable infeed in the hopper and two pair of rollers, the pressure board is 650X1100mm with a collection tray to collect the dough pieces.

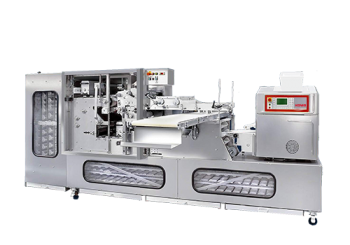

GLIMEK – Bread Line 180 Direct

The Straight Dough Line is specially made for producing bread without need for an intermediate proving time. Its a very compact dough line with capacity of up to 1800 pieces per hour and a with a weight range of 120 up to 1600 grams.

- Straight dough line Eco

There is also a Eco version of the straight dough line where the conical rounder is replaced by a hander up system that is mounted on the extended outfeed conveyor of the divider. - SD-180 Suction Dough Divider

Weight range from 120 to 1600 g, variable speed with frequency converter for 750 up to 1800 pcs/h, 100 liter stainless steel hopper with non stick coating. - CR-400 Conical Rounder

The CR-400 has centrally adjustable non-stick coated tracks, infeed at 6h, outfeed at 12 h and outfeed chute and mechanical flour duster. - CE-100 Cup Elevator

The cup elevator is mounted on the moulder, this transports the dough pieces from the rounder (or hander up) to the moulder - MO-300 Moulder

The moulder has centrally adjustable infeed in the hopper and two pair of rollers, the pressure board is 650X1100mm with a collection tray to collect the dough pieces.

OLIVER Return Chute for 723 Bagel & Bun Slicer

RC723

- Easy to clean, durable bakery white powder coat finish on frame; stainless steel chute

- Chute holds approximately one dozen bagels

- Flip-up discharge door for efficient packaging and cleaning

- Increases counter-top space for P.O.S. or other production equipment

Basic Rex

- gentle operation according to the Rex principle

- 6-, 5- and 4-row machine versions

- easy change of row number possible

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- simple operation via handwheels

- simple dough supply via chute hopper with safety light-grid

- optionally available with spreading finger belt or discharge belt

- Stainless steel design

OLIVER 758 Front Load Duo-Slicer

758

- Two options are better than one!

- Choose two slice thickness options from four standards

- Large loaf capacity – capacity of 13” loaves per side

- Easy-to-operate, front mounted push button controls

GLIMEK CE-100 Cup Elevator

CE-100

A step by step elevator for transporting dough pieces from the rounder into the moulder.

- Elevator mounted on MO-300

- The conveyor belt, 200mm wide, has riveted cups every 300 mm

- The timing of each dough piece is controlled by a photocell

- The infeed hopper guides the dough piece int an empty cup

- Capacity up to 2000 pieces/hour

- Weight range: approximately 100-1500 grams

Classic Rex

- the machine for the most stringent hygiene demands

- gentle dough processing according to the tried-and-tested Rex principle

- 6-, 5- and 4-row operation

- easy change of row numbers

- fully automated machine operation by means of servomotors optionally available

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- standard version with large shaft hopper and safety light-grid

- optionally available with roller hopper for mounting a large dough hopper

- with spreading finger belt or discharge belt

- stainless steel design

OLIVER 732 Front Load Countertop Slicer

732

- Perfect for on-demand slicing of hard-crusted breads and soft-textured sandwich loaves

- Small footprint – less than 27” wide

- Large bread capacity – up to 16” loaves

- Easy-to-operate, with convenient, front-mounted push button controls

- Front-mounted bagging scoop that adjusts for smaller loaves makes for convenient bagging

GLIMEK CE-300 Cup Elevator

CE-300

- The conveyor belt, 200mm wide, has riveted cups on every 300mm

- The timing of each dough piece is controlled by a photocell

- The infeed hopper guides the dough piece into an empty cup

- Capacity: up to 2000 pieces/hour

- Weight range: apprx. 100 – 1500 grams

GLIMEK CE-500 Cup Elevator

CE-500

- The timing of each dough piece is controlled by a photocell

- The infeed hopper guides the dough piece into an empty cup

- Additional distributing height (optional)

- Capacity: up to 3600 pieces//hour

KOENIG Rex Futura Multi

- weight range of 17 to 230g (up to 600g for only divided products) adjustable with touch panel

- maximum hourly capacity of up to 9000 pieces at 6 row operation (corresponding to 25 lifts/min.)

- optimum rounding result for varying doughs through exchangeable rounding plates and electrically adjustable rounding eccentric

- easy cleaning through collapsible roller hopper, removable hopper duster unit and removable rounding plates and dividing ledges

- large operating doors for easy access for cleaning and maintenance

- operation by PLC control and touch panel

- possibility to install special pistons , e.g. so-called Rustika pistons, for the production of square, rustic-style rolls

- optimal vibration damping during operation by means of solid cast side plates

- easy dough supply through roller feeding hopper with a dough capacity of 28 kg

- integrated shelf space for divider ledges and slider blocks

GLIMEK BL Bowl Lift

MODEL BL

With a capacity to lift up to 600 kilos this bowl lift is very versatile (removable bowl incl. dough).

The bowl lift can be designed to empty the bowl to the left or right which makes it adaptable to the bakery layout.

F series

- Fermatic Q4 has been developed to meet tomorrow’s production requirements with regard to techniques within Freezing-Proving, Retarding-Proving and Dough On Demand.

Taste and aroma are improved as the enzymes in the dough have time to develop. Delivers higher quality in the baked bread. - Speed of fans adjusted according to requirements.

Circulate precisely the right amount of air and process the dough as gently as possible. In each phase of the program the fans have precisely the speed required, thus providing an energy efficient and quiet cabinet. - The automatic system controls all processes in the cabinet, ensuring that the dough is protected against drying out and is handled as carefully as possible.

Gives the baker greater freedom and the opportunity to influence times and settings to suit the individual working day and the pace of the work. - Stable, modular frame.

Compact and stable cabinet design. - Effective 80 mm polyurethane insulation in closed units.

Keeps the cold/heat in place in the cabinet. Reduces energy consumption drastically - Floor design with well-insulated, bolted floor and strong 3 mm stainless steel sheet metal.

Very durable and keeps the cold/heat in place. - The Freezer-Prover has electrical heating coils in the floor as standard.

Counteracts damage caused by freezing and keeps the floor dry

Classic Rex Futura

- extended weight range through enlarged dividing drum

- gentle dough processing according to the tried-and-tested Rex principle

- the machine for the most stringent hygiene demands

- 6-, 5- and 4-row operation

- easy change of row numbers

- fully automated machine operation by means of servomotors optionally available

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- standard version with large shaft hopper and safety light-grid

- optionally available with roller hopper for mounting a large dough hopper

- with spreading finger belt or discharge belt

- stainless steel design

TP Infinity – Tunnel Pizza Oven

- Available in three standard widths and up to three or four sections in height, depending on model.

Suited for most pizza sizes. - Stainless steel exterior and well insulated oven chamber.

Keeps the heat inside the oven and maintains low temperature on the outside. - Digital panel provides good controls and makes it easy to set the right time and adjust the temperature up to 400 Celsius in two zones per oven chamber

- Steam canopy at infeed and outfeed to create a good working environment (not on TP10 and TP20)

- Stepless adjustment of top and bottom heating.

- Oven chamber with two different zones – the temperatures of the top and bottom heating are controlled separately for each zone, resulting in even baking.

- Stainless steel mesh conveyor.

GLIMEK BH Bulk Hopper

MODEL BH

With a volume of 575 liters as standard this bulk hopper is very efficient.

- Hopper in stainless steel – painted frame included

- Pneumatic controlled dough knife with a width of 400mm as standard (other sizes on request)

- Automatic dosing device, photocell controlled which creates an even dough level in the divider hopper and better weight accuracy

- 575 liter volume – 350 kilo dough

- Sliding plate on top of bulk hopper is included

- Support bare between Bowl lift and Bulk hopper when delivered together

- Designed to work with dividers from other suppliers (on request)

Classic Rex Plus

- gentle dough processing according to the tried-and-tested Rex principle

- the machine for the most stringent hygiene demands

- 3- and 4-row operation

- easy change of row numbers

- capacity of machine continually adjustable from 12 to max. 20 strokes per minute

- simple dough supply via roller hopper with safety light-grid

- machine operation via touch panel

- stainless steel design

Grande Rex

- 3- or 4-row operation

- max. hourly capacity: approx. 2800 pieces with max. 12 strokes/min

- simple dough supply via shaft hopper with safety light-grid

- simple operation via handwheels

- plastic drum free of oil

- stainless steel design

P Series Pizza Oven

P series

- A pizza oven that retains its heat!

Highly efficient heat distribution in 3 zones: upper, lower and front heat results in uniform baking and produces good overall economy. - Energy efficient thanks to intelligent energy savings features and well insulated oven chamber.

- Low maintenance costs.

- robust door construction.

- Tempered double glass with heat reflecting outer surface retains the heat in the oven chamber. This results in a better working climate in the kitchen.

- Thicker pizza stone that retains heat better!

GLIMEK SD-300 Suction Dough Divider

SD-300

Features

- Weight range: 1-pocket 150 to 2300 grams, 2-pocket 40 to 1000 grams

- Variable speed with frequency converter

- Capacity: 1-pocket from 750 up to 1500 pieces per hour, 2-pocket from 1500 up to 3000 pieces per hour

- Dough knife in stainless steel

- Unique emptying function (hopper reaches down to the dough knife)

- Gentle dough handling

- Dough chambers in high quality Ni.resist steel ensure high weight accuracy and long durability

- PLC touch screen

- Heavy duty construction

- 100 liter stainless steel hopper as standard

- 225 liter stainless steel hopper (optional)

- Non stick coated hopper (optional)

- Easy handling and cleaning since all covers are in stainless steel and removable

- 11 liter oil reserve, easy to fill

- Stainless steel execution

- Available with left or right outfeed

GLIMEK SD-600 Suction Dough Divider

SD-600

Features

- Weight range: 3-pocket from 150 to 3000 grams, 2/4-pocket 250 to 1700/100 to 700 grams

- Variable speed with frequency converter

- Capacity: 3-pocket from 1500 up to 4500 pieces per hour, 4-pocket from 2000 up to 6000 pieces per hour, 2-pocket from 1000 up to 3000 pieces per hour

- High quality components and choice of material

- Very user friendly 8 inch touch screen for settings and storing recipes

- Stepless adjustable pneumatic system for very gentle handling of different types of dough. Can be adjusted during operation

- Reliable dividing system with very high weight accuracy

- Separate drive on outfeed conveyor

- Smart monitored lubrication systems that give the machine a long life span

- Quick release on outfeed conveyor

- High attention on borh safety and hygienic aspects

- PLC touch screen for meny based navigation

- 100 liter stainless steel hopper as standard

- 225 liter stainless steel hopper (optional)

GLIMEK ICP Intermediate Pocket Prover

ICP

- Capacity of up to 3600 pieces per hour

- Removable plastic covers on both sides

- Belt width of 350 mm

- Made of strong special aluminum profiles

- Drum motors with frequency controlled drive as standard

- Outlet sliding plate – fixed (option)

- Outlet sliding plate – turnable 1500 mm or 2500 mm (option)

- Separate stands (option)

- Cealing suspensions (option)

Industrial Proofing lines

- Fermentation lines

Sveba-Dahlen has over 40 years of experience of manufacturing fermentation lines. The fermentation lines are manufactured in one or two level versions, and the size is calculated in view of the capacity requirements and the layout of the premises. The maximum band width is 4 meters, and the bands are threaded over the full width. A modular plastic belt is commonly selected where tins or plates are used. The fermentation channel is well insulated with cellular plastic and lined externally and internally with aluminum sheets or plastic. Most of the side panels can easily be removed to facilitate cleaning of the band. - Conveyor provers

The conveyor provers are built in length according to the requested proving time of the product. The belt width can be up to 4 meters. - Swing prover

Available in two different models, one with stainless steel covers and one with automatic climate unit built into an insulated room. A module system in width up to 3 meters which can be adjusted in height and length according to capacity and required proving time. The swings for loaves are with easy removable textile tubes and for round bread cups or baskets are used. Swing prover with automatic climate unit completely built into an insulated room with free inner passage on both sides for easy cleaning and maintenance. A two motor operation enables a great flexibility in the modification of proving time and capacity.

Indirect gas heated tunnel oven

- Separate burners for top and bottom heat

With separate burners for top and bottom heat in each zone the oven becomes very flexible and gets a very fast reaction time when adjusted for new products. - Flexible adjustment

Each zone is working independently since the temperature is set with individual temperature regulators in the same way as an electric oven. There is no need to adjust the temperature with dampers as on a traditional oven because the oven is set up at installation and there after everything is controlled with the control panel. - Energy efficiency

The oven is very energy efficient; the burners adapt their heat output to the demand from each zone. - Reliability

When a burner fails in a “standard” oven with just one burner, then the entire oven shuts down. In the Sveba-Dahlen oven only the top or bottom heat of one zone fails. - Easy to service and maintain

All components and functions such as fans, burners, electrical cabinet, motors and drives are easy to access, inspect and to service

Electrically Heated Tunnel Oven

- Materials and components

We manufacture the exterior of the oven in stainless steel. The materials in the oven chamber are specifically selected for each oven, for the baking temperature and the product range. All the ovens are insulated with rockwool to minimize the heat loss. - Heating

The electric tunnel ovens are heated by tube elements with double heating spirals. The elements are installed over and under the oven chamber, along the entire oven, and are easily accessible from the side. Each element has its heat-emitting part positioned so that the band is heated efficiently over its full width. The tube elements are specially manufactured for each individual oven for maximum control of the heat distribution and quality. On an average, a tunnel oven consists of about 12 elements per meter. - Control

The control panel is designed to give best overview and simple control displaying baking time, temperature etc. PLC control with recipe handling of process parameters and handling of alarms and data logging is available as option. Connection to a master control system is another possible choice. - Steam system

In ovens built for connection to a steam generator, a part of the first oven chamber is provided with steam spreader boxes made of acid proof stainless steel. Regulating indicator valves with dial clocks are fixed on the sides of the oven to set the correct volume. Steam control with quantity control/photocell control can be selected as an option. - Air turbulence

For many types of products, it is appropriate to use a combination of radiant heat and air circulation. If so the oven can be equipped with turbo zones. In wire mesh band ovens, air circulation is most often vertical, up through the band, in steel band ovens it is horizontal along the band. With air circulation, the baking time can be shortened, and lower temperatures utilized. This also gives the sides of the bread better color, especially by baking with tins. By controlling the speed of the drive motor, optimal turbo power of the turbo fans can be obtained

Grande Rex Futura

- 3- or 4-row operation

- max. hourly capacity: approx. 2800 pieces with 12 strokes/min

- simple dough supply via shaft hopper with safety light-grid

- simple operation via handwheels

- plastic drum free of oil

- stainless steel design

Mini Rex Multi

Weight range from 8 to 330 g (up to 140 g rounded) — depending on dough

- max. hourly capacity in the 1-, 2-, 3-row or 4-row version: 1200, 2400, 3600 or 4800 pieces

- easy and safe change of the dividing drum ledges for different weight ranges and changes of number of rows

- roller hopper for approx. 15 kg dough capacity

- all components that come in contact with the dough can be removed from the machine for easy cleaning

- stainless steel design

- Easy control with micro controller via touch panel

- all mechanical settings can be stored in the program

- direct access to stored programs

- robust industrial version with LED display

- clearly legible, 3-digit digital display

- Slot for SD memory card for backup and easy software update

OLIVER 302 Bagel & Bun Manual Slicer

302

- slices warm bagels or buns without crushing or deforming product

- Ensures a consistent cut for product uniformity

- Reduce risk of lacerations

- Suction cup feet to secure unit to table

- Easy insert knife guide

- Easy to clean, just place in dishwasher

KOENIG Roto Passat

Especially easy to maintain due to

- the door with easily exchangeable all-round sealing, no tools required

- “door-in-door” system for easy cleaning

- impact protection, inside and outside

- optimal cooling of the control elements

- quickly removable floor rotating table for easy cleaning

- light and separated maintenance lid on the front section

Hygienic finish due to

- the exclusive use of smooth surfaces made of stainless steel

- easily removable ramp, no tools required

- stainless steel labyrinth under the floor rotating table protecting the oven floor against soiling

- removable floor cover sheets – so the oven floor is quickly accessible and easy to clean

- efficient extractor fan shaft

Increased energy efficiency due to

- the new cloud device that makes for an optimal use of the quantity of water added

- “Energy+ High End” heater – setting a new benchmark for energy efficiency in rack ovens

KOENIG Passat OH

- the rack oven with standing baking trolley for bread and rolls

- reciprocal flow of hot-air above products

- design combining attractive appearance with easy operation

- touch screen operation enables easy input of required values and rapid effect on the baking process

- long working life and value

- stainless steel design

KOENIG PU Integral

- baking surface up to 140 sqm possible

- baking plate sizes: 2,500 x 1,300 mm or 3,000 x 1,300 mm

- several independent baking zones for the regulation of temperature, air volume and humidity enable optimized product quality for all baked goods

- innovative sealing system for the individual baking zones

- the production of part-baked products with very short baking times is realized with two independently working loading trolleys

- increased energy efficiency thanks to thermo oil heat exchanger

- the compact construction requires minimal space and guarantees minimal heat losses

- optionally available also without independent baking zones and with heater for oil or gas burner

Mini Rex Futura

- capacity of up to 4000 pieces/hour, set at 33 strokes/min.

- extended weight range through the combination of 2 dividing stamp sizes

- optimum rounding results via continually adjustable rounding eccentric

- roller hopper with approx. 15 kg dough capacity

- 2-row operation

- industrial PLC control with quick access keys

- also available with special stamps

- quick access keys

OLIVER Countertop Bun Divider 623

623N

- Constructed of cast iron and cast aluminum

- Sanitary stainless steel pan included

- Model 623-36 divides dough into 36 pieces up to 4 oz. (113g) each

- Optional stand available

OLIVER Semi-Automatic Bun/Divider Rounder with removable head

625N-P

- Four machines in one

- interchangeable dividing head assemblies

- quick and easy tool-free changeover

- 36, 18, 9 and 6 part divisions

- finished dough range 1 – 26 parts

- up to 5,000 pieces/hour

- dividing head assemblies are dishwasher safe

- standard unit includes 36 part dividing head and 2 dough paddles

KOENIG Industry Rex I

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 24,000 pieces with max. 50 strokes/min in the 8-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG ECO 4000

4000

- maximum hourly capacity of 5,100 pieces with 5-row operation

- entire line can be moved on wheels, with movable head machine

- top processing quality through the use of premium stainless steel materials

- space-saving compact design

- setting adjusted to Euro standard baking tray sizes

- optional additional device for optional setting face up or face down

- use of a wide range of individual stamping tools possible through carrier plate insert

- also available with prover for approx. 10 or 20 minutes final proving time

- final prover disconnectable on request

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Certo Pan M

- dough throughput of up to 600 kg per hour

- maximum hourly capacity of 7,500 pieces (square rolls) or 6,000 pieces (rounded rolls) when working with 5 rows

- infeed of dough via integrated box lifting unit

- endless dough sheet production by the use of a rotating disc hopper and an oscillating cutting knife

- exchangeable cutting rollers for varying numbers of rows for the dough sheet

- usable dough sheet width approx. 240 mm

- even dough pieces with high weight accuracy through endless dough sheet

- optimal cleaning on account of large maintenance doors and swiveling disc hopper

- easy operation with PLC control and touch panel with pictograms

KOENIG Industry Rex II

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 30,000 pieces with 50 strokes/min in the 10-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG Eco Twin

- great price-performance ratio

- 800 mm version: 6-/5-row operation

- 600 mm version: 5-/4-row operation

- pre-prover line of a length of only 3,480 mm

- with additional direct set-down as standard

- quickly changeable stamping tools and cutting tools

- made of stainless steel – of stable value over many years

- entire line sits on an underframe with wheels

- for Eco Twin 600, also available with final prover for 20 minutes final proving time

- variable set-down by means of retracting unit on to common proving trays / baking trays

- retracting lengths and steps of the dough pieces when set down are continually adjustable

- with direct set-down as standard

- available with additional Wachauer rounding station as special design

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Industry Rex III

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 42,000 pieces with 50 strokes/min in the 14-row version

- simple dough supply via roller hopper with safety light-grid

- stainless steel design

KOENIG Combiline

- hourly capacity up to 9,000 pieces.

- modular system

- easily expandable at a later stage

- modular design for the entire line

- also available with direct transfer for the setting of raw dough pieces

- variable setting onto baking trays or proving trays

- available with a working width of 600 or 800 mm

- top processing quality through the use of premium stainless steel materials

- hygienic design for easy cleaning and maintenance

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – DR-RR400

DR-RR400

- compact design

- fully automated dividing and rounding of wheat doughs and rye- -wheat doughs with a maximum rye percentage of 40%

- can be combined with Mini Rex Futura as well as Mini Rex Multi

- excellent results with the production of round, long-rolled, long-rolled and folded as well as flattened goods

- maximum hourly capacity of up to 4,000 pieces.

- weight ranges Mini Rex Futura / Mini Rex Multi

- height-adjustable calibrating head, folding net belts, lower belt and upper belt for ergonomic working with the following functions: transporting, long rolling, pressing flat

- teflonized collecting drawer for manual product removal

- also available with seeder

- quick and easy cleaning on account of plug-in elements

- stainless steel design

KOENIG Ceres 2.2

2.2

- for all doughs with a dough yield between 162 and 182

- for all doughs ranging from 100% wheat to 100% rye

- for all doughs with pre-dough and long bowl resting time

- minimal cleaning efforts on account of easy access to the parts to be cleaned, extra cleaning menu, movable dough belt sensors, removable transfer disc and belts of synthetic material

- dough divider with patented gravitation dough sheet technique

- hopper with a volume of 300 liters and 900 mm height for more bowl proving – no pre-portioning hopper required

- sensor-controlled weighing device

- designed for one-man operation

- designed in accordance with the latest applicable hygiene regulations

- electric lifting and lowering of the hopper

- shortest possible set-up times when changing dough sorts

- Siemens-S7 PLC control with touch panel

- bowl hoist with standard scraping device can be combined directly

KOENIG Industry Rex Futura

- automatic dough dividing and rounding machine according to the Rex principle

- different chamber sizes with enlarged dividing drum

- max. hourly capacity of approx. 14,400 pieces with 40 strokes/min in the 6-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG Spiral Mixer

- stable construction for demanding doughs

- dough capacity: 160 and 240 kg

- with two speeds for mixing tools and dough bowl as standard

- short mixing times with minimum dough warming

- head can be lifted and lowered hydraulically

- dough bowl removable

- hydraulic dough bowl locking

- standard version with stainless steel execution and stainless steel foot plate

- optionally available with stainless steel base frame

GLIMEK MO881 Industrial Moulder

MO881

Features

- Capacity up to 3600 pcs/hr

- Driven by tension timing belt

- Noiseless and sustainable

- Three adjustable pressure rollers with spring loaded scrapers

- Easy to clean

- Two separate pressure boards

First pressure board is delivered in two widths, 220 or 280 mm foldable, second pressure board 650X1100 mm - Collection tray with two positions

Enables outfeed with or without stop

Capacities

- Up to 3000 pcs/hr

- Weight range 30 up to 1800 grams

- Working width up to 650 mm

KOENIG KGV Combi 2000

2000

- maximum hourly capacity up to 18,000 pieces.

- 800 mm working width for top performance

- on request, available with direct transfer for the setting down of raw dough pieces

- ergonomic design

- convenient manual operation

- easy cleaning because all parts in touch with dough are optimally accessible

- optionally available with dampening/seeding and final prover

KOENIG Combiline Compact

- compact and stable frame design

- the tried-and-tested dough dividing and rounding machines Basic Rex, Classic Rex and Classic Rex Futura as head machines guarantee a truly royal roll line

- the tried-and-tested dough dividing and rounding machines Basic Rex, Classic Rex and Classic Rex Futura as head machines guarantee a truly royal roll line

- climate control with heating and dampening, highly efficient sterilisation facility for empty swings

- adjustable capacity of 15-25 strokes / min.

- ergonomic height for tray removal

- direct setting from head machine to setting unit possible

- integrated long rolling station for the production of cut rolls or long rolls

- retracting unit optionally equipped with extendible drawer for making work easier

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – G2000

G2000

- compact pre-prover with Mini Rex Futura or Mini Rex Multi as head machine

- max. hourly capacity with prover operation: 2,000-2,500 pieces, continually adjustable /

- for greater capacity without prover operation, Mini Rex Futura or Multi movable: 1,800-4,000 pieces, continually adjustable /

- weight ranges Mini Rex Futura / Mini Rex Multi

- one-row discharge belt for convenient manual removal

- prover with 100 useable cup swings, for a max. weight of each dough piece: 75 g

- proving time approx. 6 min., with a capacity of 2,000 pieces/hour

- stamping device with easily changeable stamping tools

- integrated folding/long rolling unit (e.g. for the production of Berlin rolls)

Industry Rex AW

- 6-, 8- or 10-row dough dividing and rounding machine in the weight range of 22-160 g

- dividing and rounding system developed from scratch

- continually adjustable, even slide pressure for greatest weight accuracy for different doughs

- max. hourly capacity: approx. 30,000 pieces with 50 strokes/min in the 10-row version

- change of the weight range through manually exchangeable dividing ledges and piston tools according to the Multi system

- exact dividing process through “stop and go” operation and specially shaped pre-chamber

- inner rounding drum with automatically adjustable rounding eccentric

- transfer belts between dividing drum and rounding drum can be folded up on both sides for easy cleaning

- drive of the transfer belts through cardan joint drive drums for maximum protection of the belt

- enlarged rounding drum for longer and thus more intense rounding of all doughs

- discharge spreading finger belt with cardan joint drive to avoid belt slippage

- main drives are encapsulated and completely separated from the dough area

- easy maintenance through large, removable maintenance doors

- ground clearance of 300 mm throughout for easy cleaning under the machine

- generous integrated shelves for machine accessories

KOENIG Twin Twist Mixer

- top-class industrial mixer

- stable construction for demanding doughs

- standard version with two speeds for mixing tools and dough bowl

- intense mixing with simultaneous gentle processing of fruit doughs, for example

- head can be lifted and lowered hydraulically

- dough bowl removable

- hydraulic dough bowl locking

- standard version with stainless steel execution and stainless-steel foot plate

- optionally available with stainless steel base frame and hygienic “H” build type (can be sprayed clean with water – call for further details)

KOENIG KGV I-VI – Program

- monoline for top hourly capacity or multifunctional line for the greatest possible product diversity

- hourly capacity up to 36,000 pieces.

- modular system for the configuration of the line according to your needs

- multiple rounds of cutting, seeding, lye application, etc. are possible

- final prover with insulation cladding and controlled climate available

- equipment with swing cleaning, vacuuming and infra-red sterilisation station is possible

- available with modem connection for remote maintenance

KOENIG KKM

- roll line for great product diversity

- hourly capacity of up to 7,500 pieces 5-/4-/3-row operation

- available with Classic Rex or Industrie Rex

- in compact modular design

- direct transfer for the setting of raw dough pieces possible

- essential components of the line, e.g. final prover, dampening, seeding, convolution station and cutting station can be easily added later, depending on the line configuration

- 3-time reversible cup for diversified product range

- premium quality for cut rolls through integrated pre-prover with long-rolling station

- optional final rounding device for second rounding sequence for the production of premium rustic-style rolls (e.g. Wachauer)

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – GS2000

GS2000

- compact pre-prover with Mini Rex Futura or Multi as head machine

- available in K or SL version

- max. hourly capacity with prover operation: 2,000-2,500 pieces, continually adjustable /

- for greater capacity without prover operation, Mini Rex Futura or Multi movable: 1,800-4,000 pieces, continually adjustable /

- weight ranges Mini Rex Futura / Mini Rex Multi

- prover with 145 useable swings (K version with cup swings, SL version with continuous swings), max. weight of each dough piece: approx. 100g

- optionally available also with 170 or 220 useable swings

- proving time approx. 8 min., with 145 swings and a capacity of 2,000 pieces/hour

- stamping device with easily changeable stamping tools

- integrated forming station with pre-pressure roller, drag belt, lower and upper belt with continually adjustable speed for 2-row operation, cross separation max.180 mm

- one-row discharge belt for convenient manual removal

KOENIG Menes 1

1.0

- dough throughput from 500 of up to 5,000 kg per hour

- available in working widths 800/1,000/1,200 and 1,600mm

- extreme range of dough yields processable: from 140 to 190 gr.

- dough sheet thickness of 1 mm – 50mm

- “Twin Sat” double satellite head for the most gentle dough processing

- stainless steel design

- picture-oriented and simple control of the system

KOENIG Industry Rex Plus

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity: approx. 8,400 pieces with 35 strokes/min in the 4-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG Herkules Bowl Hoist

- lifting power up to max. 1000 kg.

- tipping height adjustable in steps from approx. 50 mm to max. 3300 mm

- clamp for third-party bowls available optionally

- optionally in right-hand or left-hand version

- transversely movable (special version)

- also available for low tipping heights

- basic frame available in stainless steel

Product

Product