Proving and Stamping

KOENIG ECO 4000

4000

- maximum hourly capacity of 5,100 pieces with 5-row operation

- entire line can be moved on wheels, with movable head machine

- top processing quality through the use of premium stainless steel materials

- space-saving compact design

- setting adjusted to Euro standard baking tray sizes

- optional additional device for optional setting face up or face down

- use of a wide range of individual stamping tools possible through carrier plate insert

- also available with prover for approx. 10 or 20 minutes final proving time

- final prover disconnectable on request

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Eco Twin

- great price-performance ratio

- 800 mm version: 6-/5-row operation

- 600 mm version: 5-/4-row operation

- pre-prover line of a length of only 3,480 mm

- with additional direct set-down as standard

- quickly changeable stamping tools and cutting tools

- made of stainless steel – of stable value over many years

- entire line sits on an underframe with wheels

- for Eco Twin 600, also available with final prover for 20 minutes final proving time

- variable set-down by means of retracting unit on to common proving trays / baking trays

- retracting lengths and steps of the dough pieces when set down are continually adjustable

- with direct set-down as standard

- available with additional Wachauer rounding station as special design

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

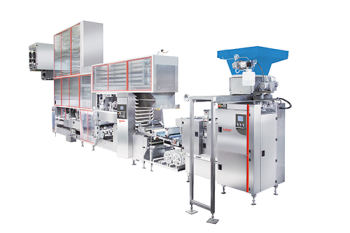

KOENIG Combiline

- hourly capacity up to 9,000 pieces.

- modular system

- easily expandable at a later stage

- modular design for the entire line

- also available with direct transfer for the setting of raw dough pieces

- variable setting onto baking trays or proving trays

- available with a working width of 600 or 800 mm

- top processing quality through the use of premium stainless steel materials

- hygienic design for easy cleaning and maintenance

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – DR-RR400

DR-RR400

- compact design

- fully automated dividing and rounding of wheat doughs and rye- -wheat doughs with a maximum rye percentage of 40%

- can be combined with Mini Rex Futura as well as Mini Rex Multi

- excellent results with the production of round, long-rolled, long-rolled and folded as well as flattened goods

- maximum hourly capacity of up to 4,000 pieces.

- weight ranges Mini Rex Futura / Mini Rex Multi

- height-adjustable calibrating head, folding net belts, lower belt and upper belt for ergonomic working with the following functions: transporting, long rolling, pressing flat

- teflonized collecting drawer for manual product removal

- also available with seeder

- quick and easy cleaning on account of plug-in elements

- stainless steel design

KOENIG KGV Combi 2000

2000

- maximum hourly capacity up to 18,000 pieces.

- 800 mm working width for top performance

- on request, available with direct transfer for the setting down of raw dough pieces

- ergonomic design

- convenient manual operation

- easy cleaning because all parts in touch with dough are optimally accessible

- optionally available with dampening/seeding and final prover

KOENIG Combiline Compact

- compact and stable frame design

- the tried-and-tested dough dividing and rounding machines Basic Rex, Classic Rex and Classic Rex Futura as head machines guarantee a truly royal roll line

- the tried-and-tested dough dividing and rounding machines Basic Rex, Classic Rex and Classic Rex Futura as head machines guarantee a truly royal roll line

- climate control with heating and dampening, highly efficient sterilisation facility for empty swings

- adjustable capacity of 15-25 strokes / min.

- ergonomic height for tray removal

- direct setting from head machine to setting unit possible

- integrated long rolling station for the production of cut rolls or long rolls

- retracting unit optionally equipped with extendible drawer for making work easier

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – G2000

G2000

- compact pre-prover with Mini Rex Futura or Mini Rex Multi as head machine

- max. hourly capacity with prover operation: 2,000-2,500 pieces, continually adjustable /

- for greater capacity without prover operation, Mini Rex Futura or Multi movable: 1,800-4,000 pieces, continually adjustable /

- weight ranges Mini Rex Futura / Mini Rex Multi

- one-row discharge belt for convenient manual removal

- prover with 100 useable cup swings, for a max. weight of each dough piece: 75 g

- proving time approx. 6 min., with a capacity of 2,000 pieces/hour

- stamping device with easily changeable stamping tools

- integrated folding/long rolling unit (e.g. for the production of Berlin rolls)

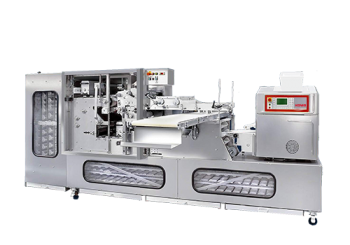

KOENIG Combiline Compact EC – Easy Clean

The modular roll line with a capacity of 33 strokes/min in Easy Clean Design

The Combiline plus EC is a modular line which fits to the requirements of your bakery. By means of your special conditions, market requirements and investment spending, you define the configuration of the line. And Koenig builds it in the way you need it. In case you will need an additional level of automation later on, the line can be easily expanded without major engineering work and with minimal disruption to your production. The Easy Clean Design offers easier cleaning, maintenance and access to all modules.

Performance features:

- max. hourly capacity of 11,880 pieces at 6-row operation and adjusted 33 strokes/min

- available in working widths of 600 or 800 mm

- with pre-proofer „plus“ with 320 usable swings

- capacity adjustable between 18 and 33 strokes/min

- climate with heating and wetting, highly effective sterilisation unit for empty swings

- with a transfer belt after the stamping station, the setting of dough pieces is even more gentle and exact

- retracting unit accessible from three sides with tray support at ergonomic height

- direct transfer from head machine to setting unit possible to convey products with high single dough piece weight to the setting unit

- optional with cross conveyance for feeding a convoluting machine

- integrated longroller unit for the production of cut rolls as option

- an entirely new user interface simplifies operation for daily production but also for changes in programs and service activities

KOENIG KGV I-VI – Program

- monoline for top hourly capacity or multifunctional line for the greatest possible product diversity

- hourly capacity up to 36,000 pieces.

- modular system for the configuration of the line according to your needs

- multiple rounds of cutting, seeding, lye application, etc. are possible

- final prover with insulation cladding and controlled climate available

- equipment with swing cleaning, vacuuming and infra-red sterilisation station is possible

- available with modem connection for remote maintenance

KOENIG KKM

- roll line for great product diversity

- hourly capacity of up to 7,500 pieces 5-/4-/3-row operation

- available with Classic Rex or Industrie Rex

- in compact modular design

- direct transfer for the setting of raw dough pieces possible

- essential components of the line, e.g. final prover, dampening, seeding, convolution station and cutting station can be easily added later, depending on the line configuration

- 3-time reversible cup for diversified product range

- premium quality for cut rolls through integrated pre-prover with long-rolling station

- optional final rounding device for second rounding sequence for the production of premium rustic-style rolls (e.g. Wachauer)

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – GS2000

GS2000

- compact pre-prover with Mini Rex Futura or Multi as head machine

- available in K or SL version

- max. hourly capacity with prover operation: 2,000-2,500 pieces, continually adjustable /

- for greater capacity without prover operation, Mini Rex Futura or Multi movable: 1,800-4,000 pieces, continually adjustable /

- weight ranges Mini Rex Futura / Mini Rex Multi

- prover with 145 useable swings (K version with cup swings, SL version with continuous swings), max. weight of each dough piece: approx. 100g

- optionally available also with 170 or 220 useable swings

- proving time approx. 8 min., with 145 swings and a capacity of 2,000 pieces/hour

- stamping device with easily changeable stamping tools

- integrated forming station with pre-pressure roller, drag belt, lower and upper belt with continually adjustable speed for 2-row operation, cross separation max.180 mm

- one-row discharge belt for convenient manual removal

KOENIG KGV PLUS

Uniquely high performance of 100 strokes/min for a great variety of rolls

Performance features:

- the new type of industrial bread roll line for different products, such as hamburgers, hot dogs, milk rolls, donuts, brioche buns, etc.

- for a maximum output of 72,000 pieces/hour in 12-row execution

- high product quality and preservation of the dough structure, compared to extruder solutions

- easy processing of doughs with a developed dough structure or heterogeneous doughs with ingredients such as raisins or nuts

- the heart of the system is the T-Rex AW, a completely new dough dividing and rounding machine with a capacity of 100 strokes/min. for different dough consistencies and high weight accuracy

- the T-Rex AW offers a wide weight range of 25 to 70g

- a proofer ensures gentle fermentation of the dough pieces

- a new multifunctional belt stamping unit provides accurate and central punching at high power, e.g. for donuts or bagels

- forming station for a high product variety

- the cleanliness and accessibility of the KGV plus are ensured by the open design, generous stainless steel service doors and collecting drawers under the line

Bakery Equipment

Bakery Equipment