Dough Sheeting System

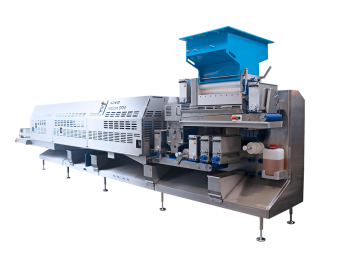

KOENIG Artisan SFC

- wide feeding belt for convenient dough feeding

- dough belt duster with large storage container and controllable drive for even dusting of the dough belt

- touch panel with pictograms for language-independent operation

- quick and easy adjustment of the machine by means of pre-installed standard programs

- max. 50 programs can be stored

- guillotine and stamping station for a maximum product variety

- dough sheet calibration system by means of innovative calibration ledges

- optionally available with dampening and seeding unit

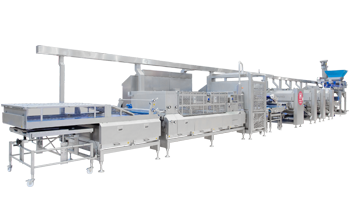

KOENIG ARTISAN SFM EC

The dough sheeting line for large and fine-pore doughs in Easy Clean Design

Performance features:

- for easy cleaning, maintenance and access to all modules, Koenig has applied the “Easy Clean” Design

- dough throughput of 400 to 1,200 kg per hour for rolls and 400 to 1,500 kg per hour for breads

- performance with angular rolls: 16,200 pieces/hour at 6-row operation (45 strokes/min.)

- performance with rounded rolls: 11,800 pieces/hour at 6-row operation (33 strokes/min.)

- absolutely gentle processing of fine- and large-pore doughs due to multiple forming rollers, adjustable for individual dough yields and bowl resting time

- new kind of dough sheet forming for gentle dough handling:

- preformer with 3-roll satellite, counter-roller and scraper for gentle preforming of the dough sheet

- a dough sheet former ensures a homogeneous dough sheet, reduction of machine length and thus reduced footprint

- for an even dough sheet and improved weight accuracy, especially for doughs with longer bowl resting time

- systems often have residual dough of up to 15%

- modular system: Modules such as forming station, seeding stations, proofer etc. available and can be retrofitted at any time

- integrated weighing system for weight-accurate production

- exchangeable cutting rollers for different dough sheet rows

- intuitive control by PLC control with 14 inch touch panel with pictograms and 99 storable programs

KOENIG Certo Pan M

- dough throughput of up to 600 kg per hour

- maximum hourly capacity of 7,500 pieces (square rolls) or 6,000 pieces (rounded rolls) when working with 5 rows

- infeed of dough via integrated box lifting unit

- endless dough sheet production by the use of a rotating disc hopper and an oscillating cutting knife

- exchangeable cutting rollers for varying numbers of rows for the dough sheet

- usable dough sheet width approx. 240 mm

- even dough pieces with high weight accuracy through endless dough sheet

- optimal cleaning on account of large maintenance doors and swiveling disc hopper

- easy operation with PLC control and touch panel with pictograms

KOENIG Ceres 2.2

2.2

- for all doughs with a dough yield between 162 and 182

- for all doughs ranging from 100% wheat to 100% rye

- for all doughs with pre-dough and long bowl resting time

- minimal cleaning efforts on account of easy access to the parts to be cleaned, extra cleaning menu, movable dough belt sensors, removable transfer disc and belts of synthetic material

- dough divider with patented gravitation dough sheet technique

- hopper with a volume of 300 liters and 900 mm height for more bowl proving – no pre-portioning hopper required

- sensor-controlled weighing device

- designed for one-man operation

- designed in accordance with the latest applicable hygiene regulations

- electric lifting and lowering of the hopper

- shortest possible set-up times when changing dough sorts

- Siemens-S7 PLC control with touch panel

- bowl hoist with standard scraping device can be combined directly

KOENIG Menes 1

1.0

- dough throughput from 500 of up to 5,000 kg per hour

- available in working widths 800/1,000/1,200 and 1,600mm

- extreme range of dough yields processable: from 140 to 190 gr.

- dough sheet thickness of 1 mm – 50mm

- “Twin Sat” double satellite head for the most gentle dough processing

- stainless steel design

- picture-oriented and simple control of the system

Bakery Equipment

Bakery Equipment