Dividing and Rounding

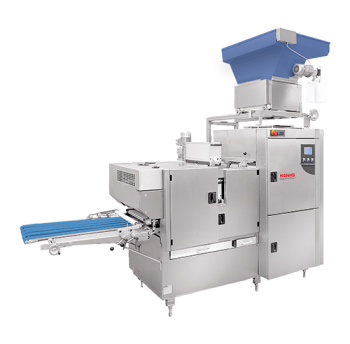

Basic Rex

- gentle operation according to the Rex principle

- 6-, 5- and 4-row machine versions

- easy change of row number possible

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- simple operation via handwheels

- simple dough supply via chute hopper with safety light-grid

- optionally available with spreading finger belt or discharge belt

- Stainless steel design

Classic Rex

- the machine for the most stringent hygiene demands

- gentle dough processing according to the tried-and-tested Rex principle

- 6-, 5- and 4-row operation

- easy change of row numbers

- fully automated machine operation by means of servomotors optionally available

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- standard version with large shaft hopper and safety light-grid

- optionally available with roller hopper for mounting a large dough hopper

- with spreading finger belt or discharge belt

- stainless steel design

KOENIG Rex Futura Multi

- weight range of 17 to 230g (up to 600g for only divided products) adjustable with touch panel

- maximum hourly capacity of up to 9000 pieces at 6 row operation (corresponding to 25 lifts/min.)

- optimum rounding result for varying doughs through exchangeable rounding plates and electrically adjustable rounding eccentric

- easy cleaning through collapsible roller hopper, removable hopper duster unit and removable rounding plates and dividing ledges

- large operating doors for easy access for cleaning and maintenance

- operation by PLC control and touch panel

- possibility to install special pistons , e.g. so-called Rustika pistons, for the production of square, rustic-style rolls

- optimal vibration damping during operation by means of solid cast side plates

- easy dough supply through roller feeding hopper with a dough capacity of 28 kg

- integrated shelf space for divider ledges and slider blocks

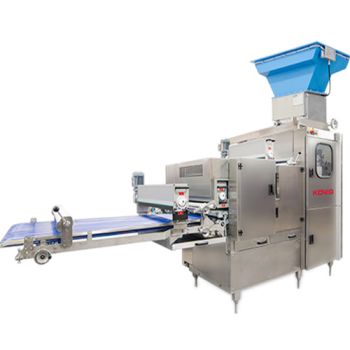

Classic Rex Futura

- extended weight range through enlarged dividing drum

- gentle dough processing according to the tried-and-tested Rex principle

- the machine for the most stringent hygiene demands

- 6-, 5- and 4-row operation

- easy change of row numbers

- fully automated machine operation by means of servomotors optionally available

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- standard version with large shaft hopper and safety light-grid

- optionally available with roller hopper for mounting a large dough hopper

- with spreading finger belt or discharge belt

- stainless steel design

Classic Rex Plus

- gentle dough processing according to the tried-and-tested Rex principle

- the machine for the most stringent hygiene demands

- 3- and 4-row operation

- easy change of row numbers

- capacity of machine continually adjustable from 12 to max. 20 strokes per minute

- simple dough supply via roller hopper with safety light-grid

- machine operation via touch panel

- stainless steel design

Grande Rex

- 3- or 4-row operation

- max. hourly capacity: approx. 2800 pieces with max. 12 strokes/min

- simple dough supply via shaft hopper with safety light-grid

- simple operation via handwheels

- plastic drum free of oil

- stainless steel design

Grande Rex Futura

- 3- or 4-row operation

- max. hourly capacity: approx. 2800 pieces with 12 strokes/min

- simple dough supply via shaft hopper with safety light-grid

- simple operation via handwheels

- plastic drum free of oil

- stainless steel design

Mini Rex Multi

Weight range from 8 to 330 g (up to 140 g rounded) — depending on dough

- max. hourly capacity in the 1-, 2-, 3-row or 4-row version: 1200, 2400, 3600 or 4800 pieces

- easy and safe change of the dividing drum ledges for different weight ranges and changes of number of rows

- roller hopper for approx. 15 kg dough capacity

- all components that come in contact with the dough can be removed from the machine for easy cleaning

- stainless steel design

- Easy control with micro controller via touch panel

- all mechanical settings can be stored in the program

- direct access to stored programs

- robust industrial version with LED display

- clearly legible, 3-digit digital display

- Slot for SD memory card for backup and easy software update

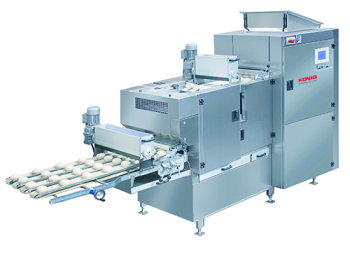

Mini Rex Futura

- capacity of up to 4000 pieces/hour, set at 33 strokes/min.

- extended weight range through the combination of 2 dividing stamp sizes

- optimum rounding results via continually adjustable rounding eccentric

- roller hopper with approx. 15 kg dough capacity

- 2-row operation

- industrial PLC control with quick access keys

- also available with special stamps

- quick access keys

KOENIG Industry Rex I

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 24,000 pieces with max. 50 strokes/min in the 8-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG Certo Pan M

- dough throughput of up to 600 kg per hour

- maximum hourly capacity of 7,500 pieces (square rolls) or 6,000 pieces (rounded rolls) when working with 5 rows

- infeed of dough via integrated box lifting unit

- endless dough sheet production by the use of a rotating disc hopper and an oscillating cutting knife

- exchangeable cutting rollers for varying numbers of rows for the dough sheet

- usable dough sheet width approx. 240 mm

- even dough pieces with high weight accuracy through endless dough sheet

- optimal cleaning on account of large maintenance doors and swiveling disc hopper

- easy operation with PLC control and touch panel with pictograms

KOENIG Industry Rex II

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 30,000 pieces with 50 strokes/min in the 10-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG Industry Rex III

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 42,000 pieces with 50 strokes/min in the 14-row version

- simple dough supply via roller hopper with safety light-grid

- stainless steel design

KOENIG Ceres 2.2

2.2

- for all doughs with a dough yield between 162 and 182

- for all doughs ranging from 100% wheat to 100% rye

- for all doughs with pre-dough and long bowl resting time

- minimal cleaning efforts on account of easy access to the parts to be cleaned, extra cleaning menu, movable dough belt sensors, removable transfer disc and belts of synthetic material

- dough divider with patented gravitation dough sheet technique

- hopper with a volume of 300 liters and 900 mm height for more bowl proving – no pre-portioning hopper required

- sensor-controlled weighing device

- designed for one-man operation

- designed in accordance with the latest applicable hygiene regulations

- electric lifting and lowering of the hopper

- shortest possible set-up times when changing dough sorts

- Siemens-S7 PLC control with touch panel

- bowl hoist with standard scraping device can be combined directly

KOENIG Industry Rex Futura

- automatic dough dividing and rounding machine according to the Rex principle

- different chamber sizes with enlarged dividing drum

- max. hourly capacity of approx. 14,400 pieces with 40 strokes/min in the 6-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

Industry Rex AW

- 6-, 8- or 10-row dough dividing and rounding machine in the weight range of 22-160 g

- dividing and rounding system developed from scratch

- continually adjustable, even slide pressure for greatest weight accuracy for different doughs

- max. hourly capacity: approx. 30,000 pieces with 50 strokes/min in the 10-row version

- change of the weight range through manually exchangeable dividing ledges and piston tools according to the Multi system

- exact dividing process through “stop and go” operation and specially shaped pre-chamber

- inner rounding drum with automatically adjustable rounding eccentric

- transfer belts between dividing drum and rounding drum can be folded up on both sides for easy cleaning

- drive of the transfer belts through cardan joint drive drums for maximum protection of the belt

- enlarged rounding drum for longer and thus more intense rounding of all doughs

- discharge spreading finger belt with cardan joint drive to avoid belt slippage

- main drives are encapsulated and completely separated from the dough area

- easy maintenance through large, removable maintenance doors

- ground clearance of 300 mm throughout for easy cleaning under the machine

- generous integrated shelves for machine accessories

KOENIG INDUSTRY REX COMPACT AW

COMPACT AW

The Industry Rex Compact AW offers an ideal balance between weight accuracy and gentle dough processing. The variable separation of the dividing pistons and rows of this dough dividing and rounding machine allows to cover a weight range from 25 to 350g in only one machine – and nevertheless in compact design. To achieve this, the proven „Multi“ principle with easily exchangeable dividing ledges has been applied to this machine.

Performance features:

- the automatic dough dividing and rounding machine can operate in up to 10 rows

- high weight range of 28-350g with only one machine by means of variable separation of dividing pistons and rows

- hourly capacity of up to 30,000 pieces at 50 strokes/min

- proven Koenig pre-portioning unit

- the continuously adjustable, absolutely even pusher pressure ensures highest weight accuracy for various dough types and consistencies manually changeable dividing ledges and dividing pistons for changing the weight range according to the system Multi

- inner rounding drum with automatically adjustable rounding eccentric

- swiveling dividing drum for compact design

- discharge spreading finger belt adjustable to separations/rows

- rounding unit for gentle rounding process guarantees optimum product quality

- easy operation with touch display

Cleaning and Maintenance:

- tool-free exchangeable dividing ledges including dividing pistons

- easy cleaning with stainless steel surfaces

- large, removable maintenance doors

- drives completely separated from the dough area

- entirely removable rounding belt and rounding drum

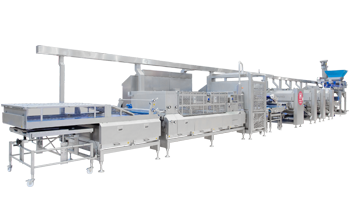

KOENIG Menes 1

1.0

- dough throughput from 500 of up to 5,000 kg per hour

- available in working widths 800/1,000/1,200 and 1,600mm

- extreme range of dough yields processable: from 140 to 190 gr.

- dough sheet thickness of 1 mm – 50mm

- “Twin Sat” double satellite head for the most gentle dough processing

- stainless steel design

- picture-oriented and simple control of the system

KOENIG Industry Rex Plus

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity: approx. 8,400 pieces with 35 strokes/min in the 4-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG INDUSTRY T-REX AW

The high-performance dividing and rounding machine T-Rex AW achieves with specially designed rounding ledges the high output of 100 strokes/min. The dough pieces are thereby gently and virtually smooth rounded.

Performance features:

- the dough dividing and rounding machine T-Rex AW offers a wide weight range of 25 to 70g and can operate in up to 12 rows

- max. hourly capacity of 72,000 pieces at 12-row operation

- the machine in „AW“ version (accurate weight), offers high weight accuracy and at the same time high dough protection

- the dough pieces are divided according to the proven „Rex“ principle with patented pre-portioning and gentle dough division in the dividing drum

- the dough pieces are transferred to a rounding belt and gently rounded at high speed with specially designed rounding ledges

Bakery Equipment

Bakery Equipment